Auswahl von LCD-Schnittstellen für industrielle Panel-PCs und Monitore

Technische Überlegungen, die über die grundlegende Signalkompatibilität hinausgehen Bei industriellen Panel-PC- und Monitorprojekten ist die Auswahl der LCD-Schnittstelle ...

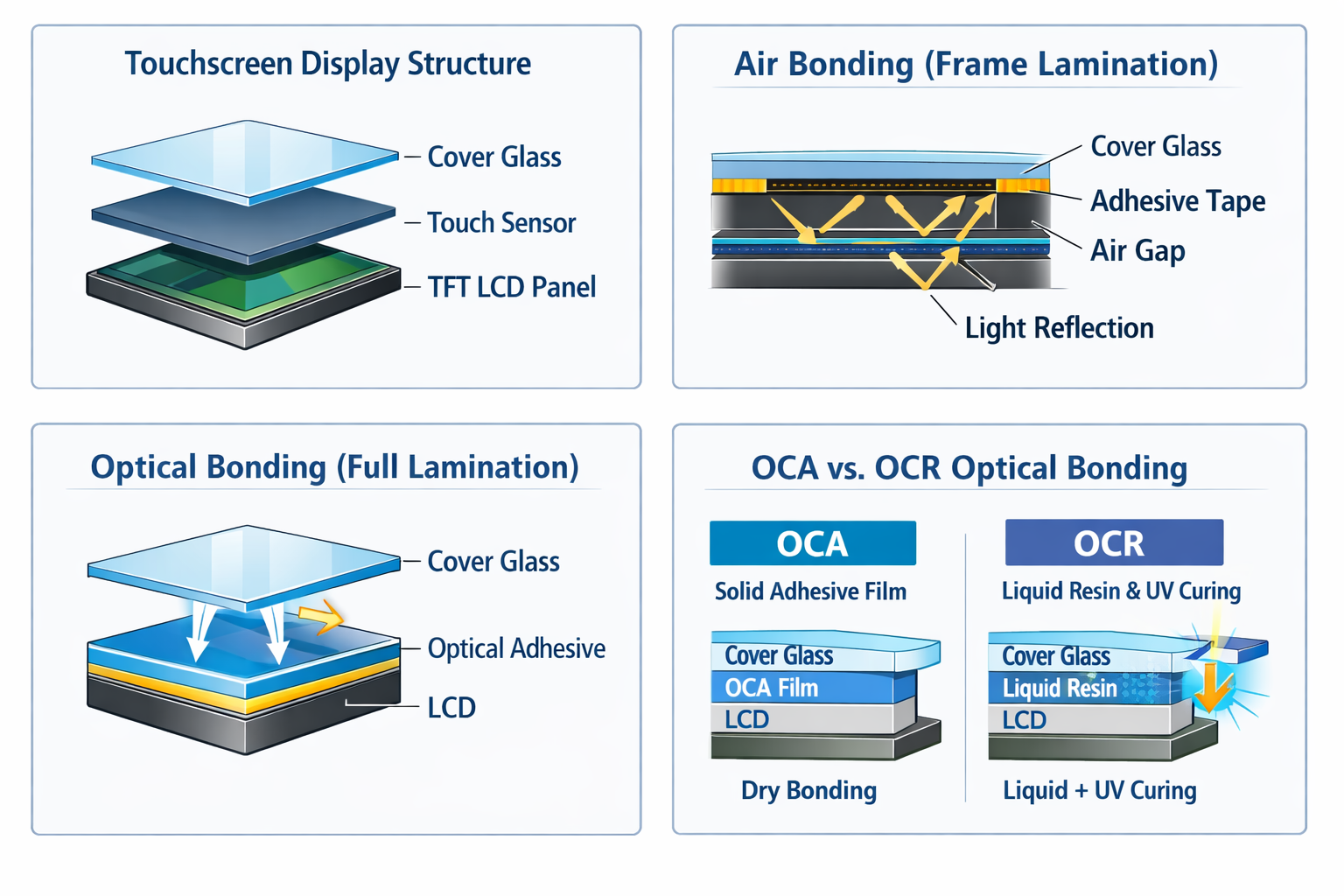

In modern touch display manufacturing, screen bonding technology plays a critical role in determining display clarity, durability, touch performance, and environmental resistance.

Two bonding methods are widely used today: Air Bonding (Frame Lamination) and Optical Bonding (Full Lamination).

This article provides a clear, engineering-focused comparison to help you understand how these technologies work, their differences, and which solution is best suited for industrial and commercial applications.

A typical touch display module consists of three main layers:

These layers must be laminated together to form a complete display.

Depending on how the layers are bonded, screen bonding can be divided into:

The bonding method directly affects optical performance, durability, touch sensitivity, and reliability, especially in industrial or outdoor environments.

Air bonding, also known as frame lamination, is a traditional bonding method where the touchscreen and LCD are bonded only around the edges using adhesive tape.

Eine air gap remains between the touch panel and the display.

Air bonding is commonly used in entry-level or indoor devices where cost is the primary concern and environmental exposure is limited.

Optical bonding, also called full lamination or direct bonding, involves bonding the cover glass or touch panel directly to the display using an optically clear adhesive.

This process eliminates the air gap entirely.

By removing the air interface, optical bonding significantly improves both optical and mechanical performance, making it the preferred solution for industrial, outdoor, and mission-critical displays.

Optical bonding is widely applied in industrial equipment, medical devices, automotive displays, kiosks, and outdoor terminals.

| Feature | Optical Bonding (Full Lamination) | Air Bonding (Frame Lamination) |

|---|---|---|

| Air Gap | None | Present |

| Display Clarity | High contrast, low reflection | Reduced due to reflections |

| Touch Sensitivity | High | Moderate |

| Durability | Strong structural bonding | Weaker over time |

| Dust & Moisture Resistance | Excellent | Limited |

| Lesbarkeit im Freien | Excellent | Poor |

| Repair Complexity | Higher | Easier |

For industrial and outdoor applications, optical bonding is strongly recommended.

Optical bonding can be classified based on the adhesive used in the bonding process.

OCA is a solid, pre-cured adhesive film used in dry optical bonding.

Key features:

OCA is commonly used in smartphones, tablets, and compact touch displays where precision is critical.

OCR is a liquid adhesive applied between layers and then cured using UV or heat.

Key features:

OCR is widely used in large-format displays, industrial monitors, and rugged equipment.

Optical bonding delivers several performance and reliability advantages:

Choose Optical Bonding if:

Choose Air Bonding if:

Screen bonding technology directly affects the performance, reliability, and lifespan of a display.

While air bonding remains a cost-effective solution for basic applications, optical bonding has become the industry standard for industrial, outdoor, and high-performance displays.

If you are designing or selecting a display for demanding environments, optical bonding is no longer an upgrade—it is a necessity.

Need help choosing the right bonding technology for your project?

Our engineering team can help evaluate your application requirements and recommend the most suitable solution.

Technische Überlegungen, die über die grundlegende Signalkompatibilität hinausgehen Bei industriellen Panel-PC- und Monitorprojekten ist die Auswahl der LCD-Schnittstelle ...

Warum ein höherer Schutz nicht immer eine höhere Zuverlässigkeit bedeutet Bei industriellen Panel-PC-Projekten bedeutet IP ...

1. Verständnis der Probleme mit kapazitiven Touchscreens Kapazitive Touchscreens sind in industriellen und kommerziellen Systemen weit verbreitet, da sie ...

1. Verständnis von “nicht reagierenden” Touchscreens Ein nicht reagierender Touchscreen bezieht sich auf einen Zustand, bei dem die Berührungseingabe ...

Teilen Sie Ihre Bewerbung und die wichtigsten Anforderungen für Touch-Monitore oder Panel-PCs. Unsere Ingenieure prüfen die Machbarkeit, die Risiken und empfehlen die richtige Konfigurationsrichtung.