Auswahl von LCD-Schnittstellen für industrielle Panel-PCs und Monitore

Technische Überlegungen, die über die grundlegende Signalkompatibilität hinausgehen Bei industriellen Panel-PC- und Monitorprojekten ist die Auswahl der LCD-Schnittstelle ...

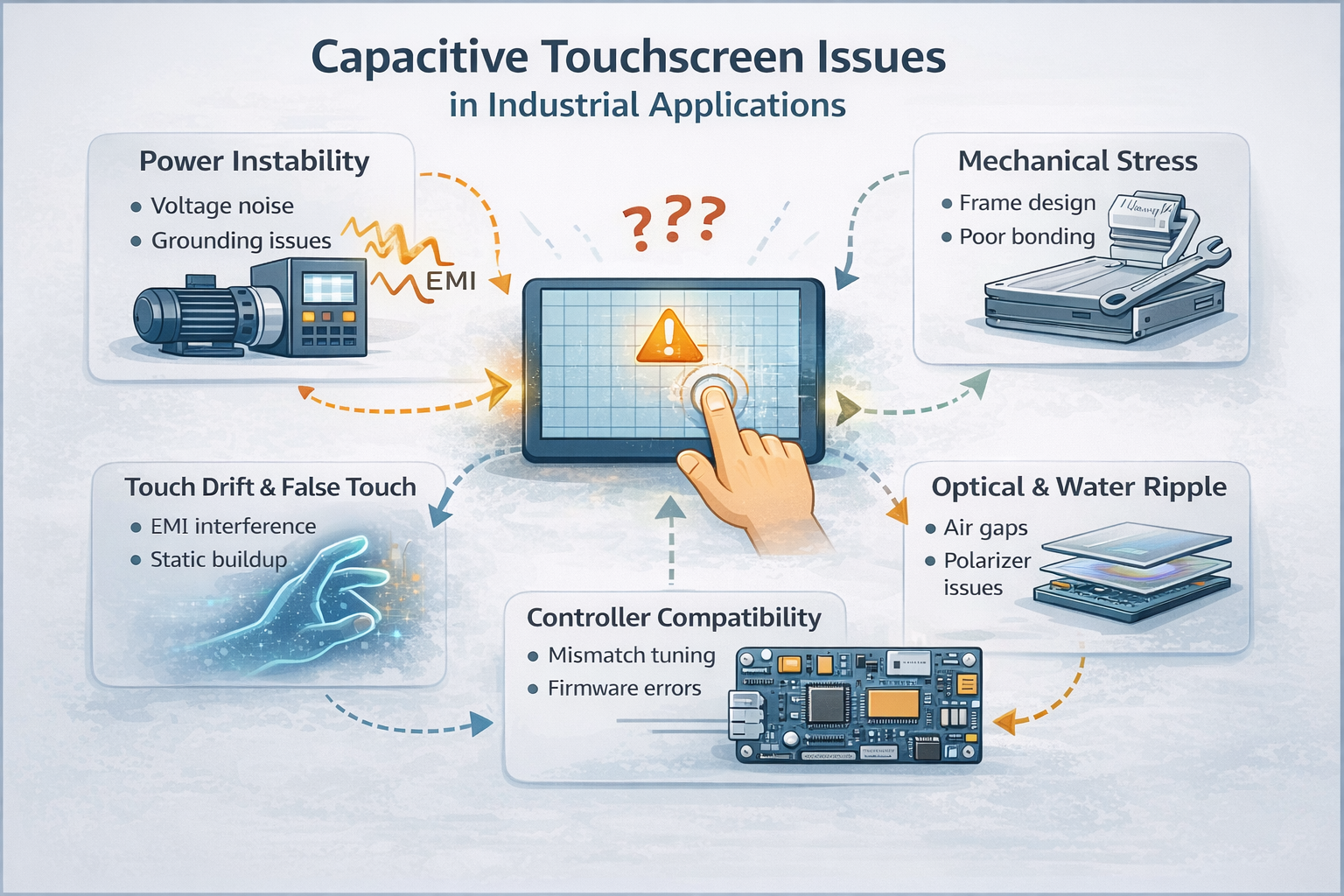

Capacitive touchscreens are widely used in industrial and commercial systems due to their high sensitivity and multi-touch capability.

However, in real-world deployments, touch-related issues are often the result of system-level interactions, rather than isolated component defects.

In industrial environments, capacitive touch behavior is influenced by electrical design, mechanical integration, firmware tuning, and application conditions.

Understanding these factors is essential for proper selection, integration, and long-term reliability.

From an engineering perspective, most capacitive touchscreen issues fall into the following categories.

Typical manifestations

Common contributing factors

In many cases, the touch sensor itself remains functional, while system conditions prevent stable signal detection.

Typical manifestations

Engineering causes

These behaviors are commonly observed during integration and pilot phases and should be evaluated under real operating conditions.

Typical manifestations

Engineering causes

Sensitivity issues are typically addressed through stack-up design and firmware optimization, rather than hardware replacement.

Ghost touch refers to touch events being registered without physical contact.

Common contributors

Ghost touch issues are strongly environment-dependent and are best mitigated through system-level electrical and mechanical design improvements.

Certain visual artifacts, such as water ripple or Newton-ring-like effects, can appear when gaps exist between the LCM and the capacitive touch panel.

Contributing factors

Depending on the application, solutions may include full lamination, alternative polarizer selection, or mechanical spacing optimization.

A common mistake in addressing capacitive touch issues is assuming that observed problems indicate defective touch sensors or controllers.

In industrial systems, many touch-related issues:

Early system-level evaluation significantly reduces repeated failures and redesign cycles.

To minimize touch-related issues, industrial projects typically evaluate:

These considerations are best addressed before mass production, during the prototype and validation stages.

If your application involves:

an engineering review is recommended to assess suitability and risk before deployment.

This article is intended as a technical reference for understanding capacitive touchscreen behavior and failure modes in industrial applications.

It focuses on engineering evaluation rather than step-by-step repair procedures.

Technische Überlegungen, die über die grundlegende Signalkompatibilität hinausgehen Bei industriellen Panel-PC- und Monitorprojekten ist die Auswahl der LCD-Schnittstelle ...

Warum ein höherer Schutz nicht immer eine höhere Zuverlässigkeit bedeutet Bei industriellen Panel-PC-Projekten bedeutet IP ...

1. Verständnis der Probleme mit kapazitiven Touchscreens Kapazitive Touchscreens sind in industriellen und kommerziellen Systemen weit verbreitet, da sie ...

1. Verständnis von “nicht reagierenden” Touchscreens Ein nicht reagierender Touchscreen bezieht sich auf einen Zustand, bei dem die Berührungseingabe ...

Teilen Sie Ihre Bewerbung und die wichtigsten Anforderungen für Touch-Monitore oder Panel-PCs. Unsere Ingenieure prüfen die Machbarkeit, die Risiken und empfehlen die richtige Konfigurationsrichtung.