産業用パネルPCとモニターにおけるLCDインターフェースの選択

基本的な信号互換性を超えたエンジニアリングの考慮事項 産業用パネルPCおよびモニタープロジェクトでは、LCDインターフェースの選択が重要です。 ...

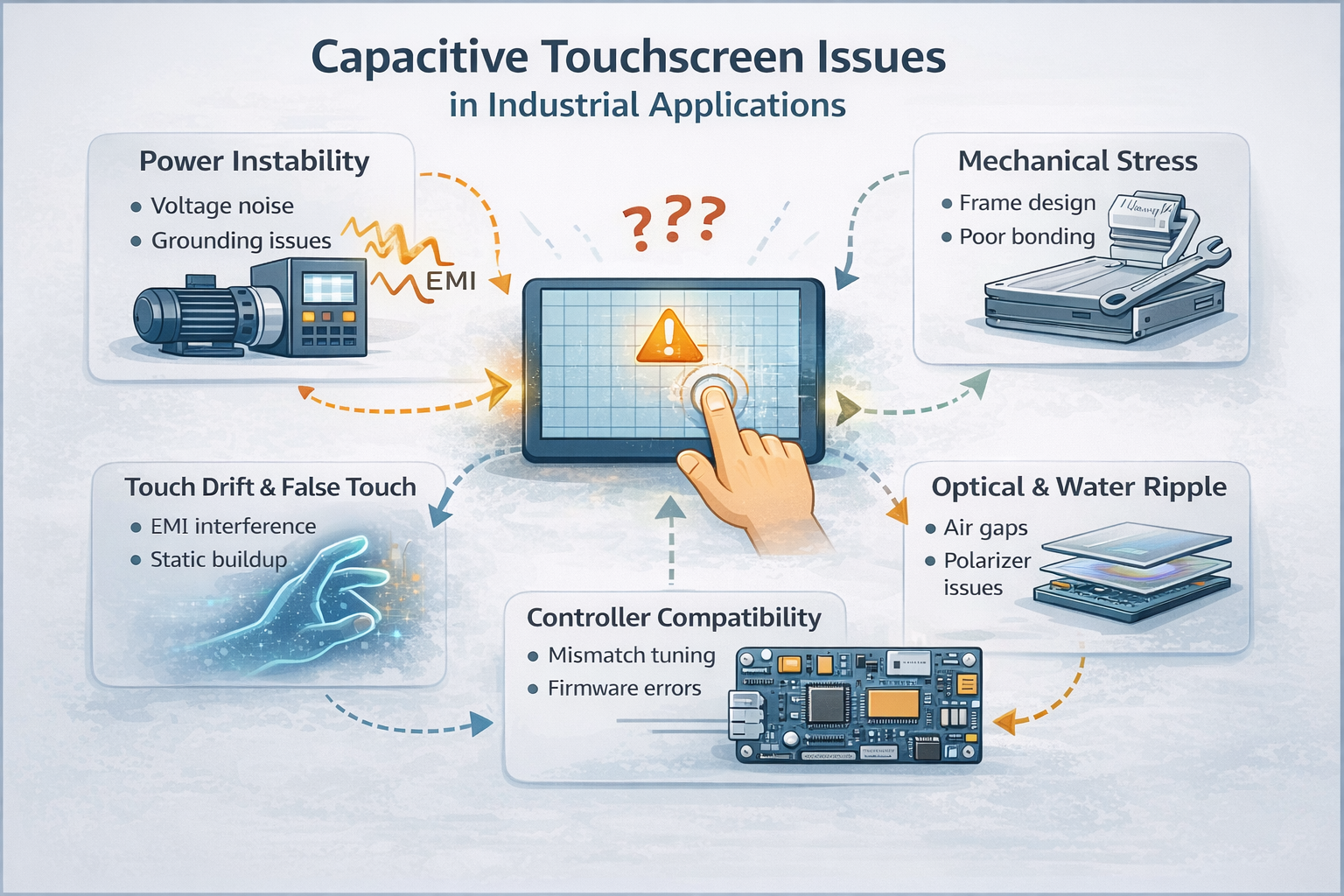

Capacitive touchscreens are widely used in industrial and commercial systems due to their high sensitivity and multi-touch capability.

However, in real-world deployments, touch-related issues are often the result of system-level interactions, rather than isolated component defects.

In industrial environments, capacitive touch behavior is influenced by electrical design, mechanical integration, firmware tuning, and application conditions.

Understanding these factors is essential for proper selection, integration, and long-term reliability.

From an engineering perspective, most capacitive touchscreen issues fall into the following categories.

Typical manifestations

Common contributing factors

In many cases, the touch sensor itself remains functional, while system conditions prevent stable signal detection.

Typical manifestations

Engineering causes

These behaviors are commonly observed during integration and pilot phases and should be evaluated under real operating conditions.

Typical manifestations

Engineering causes

Sensitivity issues are typically addressed through stack-up design and firmware optimization, rather than hardware replacement.

Ghost touch refers to touch events being registered without physical contact.

Common contributors

Ghost touch issues are strongly environment-dependent and are best mitigated through system-level electrical and mechanical design improvements.

Certain visual artifacts, such as water ripple or Newton-ring-like effects, can appear when gaps exist between the LCM and the capacitive touch panel.

Contributing factors

Depending on the application, solutions may include full lamination, alternative polarizer selection, or mechanical spacing optimization.

A common mistake in addressing capacitive touch issues is assuming that observed problems indicate defective touch sensors or controllers.

In industrial systems, many touch-related issues:

Early system-level evaluation significantly reduces repeated failures and redesign cycles.

To minimize touch-related issues, industrial projects typically evaluate:

These considerations are best addressed before mass production, during the prototype and validation stages.

If your application involves:

an engineering review is recommended to assess suitability and risk before deployment.

This article is intended as a technical reference for understanding capacitive touchscreen behavior and failure modes in industrial applications.

段階的な修理手順よりも、工学的な評価に重点を置いている。.

基本的な信号互換性を超えたエンジニアリングの考慮事項 産業用パネルPCおよびモニタープロジェクトでは、LCDインターフェースの選択が重要です。 ...

産業用パネルPCプロジェクトにおいて、IP保護等級が高くても信頼性が高いとは限らない理由 ...

1.静電容量式タッチスクリーンの問題を理解する 静電容量式タッチスクリーンは、以下の理由により産業用および商業用システムで広く使用されている。 ...

1.非反応型」タッチスクリーンを理解する 非反応型タッチスクリーンとは、タッチ入力が「非反応型」であることを意味します。 ...

あなたのアプリケーションと主な要件を共有する タッチモニター または パネルPC. 当社のエンジニアは、実現可能性、リスクを検討し、適切な構成の方向性を提案します。.