اختيار واجهة LCD لأجهزة الكمبيوتر الشخصية والشاشات ذات اللوحات الصناعية

اعتبارات هندسية تتجاوز توافق الإشارات الأساسية في مشاريع الحواسيب الشخصية والشاشات ذات اللوحات الصناعية، اختيار واجهة LCD ...

أن IK10 touch screen is designed to withstand severe mechanical impact in industrial and public environments where reliability and durability are critical.

In 2026, IK10-rated touchscreens are widely used in industrial control systems, outdoor kiosks, transportation equipment, energy infrastructure, and public-access terminals, where screens must resist vandalism, accidental impact, and long-term physical stress.

This guide explains:

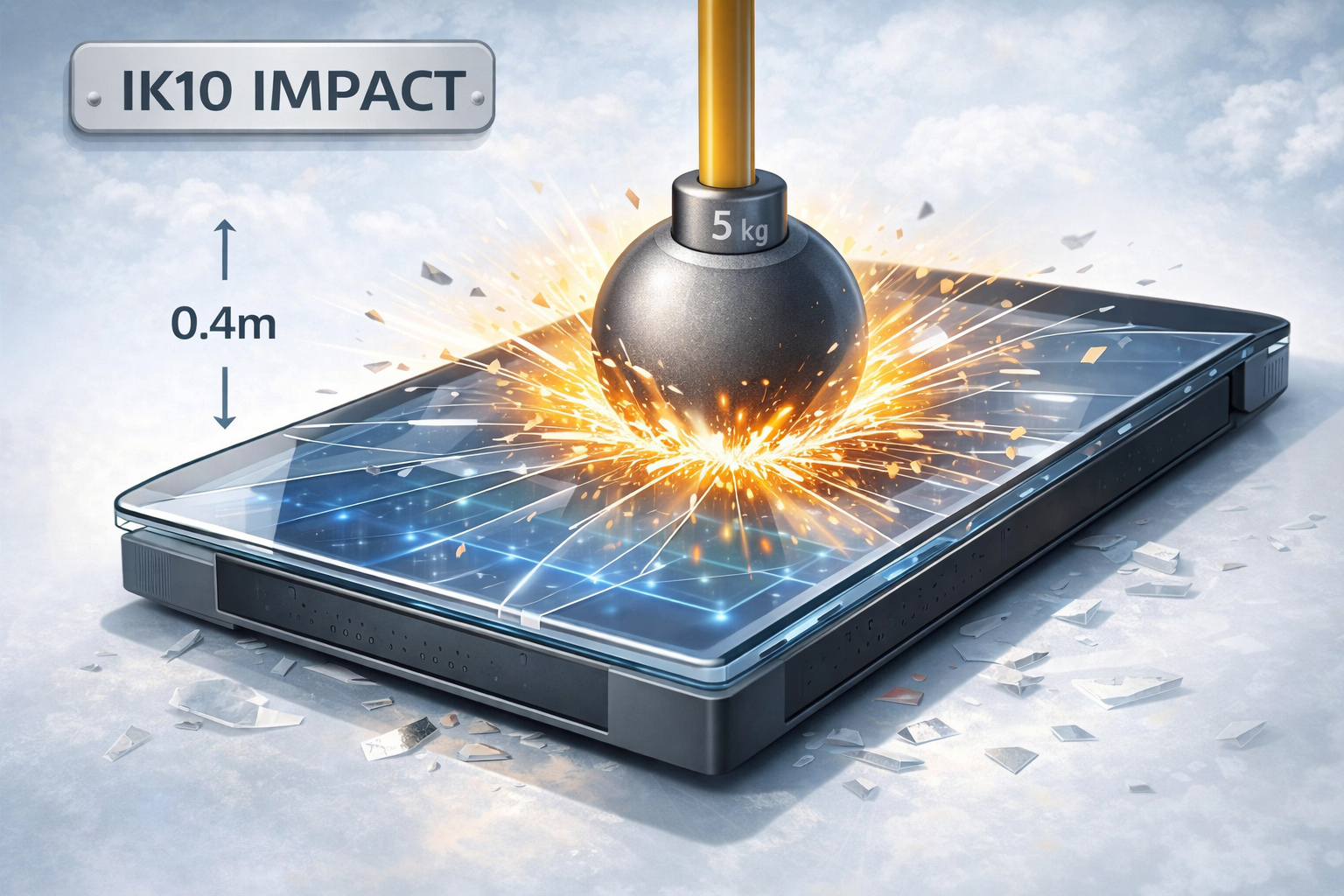

أن IK10 touch screen refers to a touchscreen that meets the IK10 impact resistance level, the highest rating defined by IEC / EN 62262.

The IK rating system measures resistance to mechanical impact, not protection against water or dust (which is covered by IP ratings).

For industrial and public-facing systems, IK10 protection means:

In real-world environments, IK10-rated touchscreens are designed to tolerate uncontrolled physical interaction.

Typical scenarios include:

This level of protection is especially important for public-access systems, transportation terminals, and industrial equipment, where user behavior cannot be fully controlled and maintenance access may be limited.

A common misunderstanding in industrial projects is confusing IK ratings with IP ratings.

| Rating | What It Measures | Typical Concern |

|---|---|---|

| IK Rating | Impact resistance | Physical damage, vandalism |

| IP Rating | Ingress protection | Dust, water, moisture |

An IK10 touchscreen does not automatically guarantee dust or water protection.

In many applications, IK10 impact resistance is combined with IP65 or higher ingress protection to ensure full environmental durability.

IK ratings are defined by IEC / EN 62262, using standardized mechanical impact tests.

For IK10:

For industrial projects, verified IK10 compliance ensures that the touchscreen has been validated under standardized test conditions, reducing risk during deployment.

Not all IK10 touchscreens perform the same in real applications. Proper design involves more than simply using thicker glass.

Most IK10 touchscreens use:

For outdoor use, anti-glare (AG) أو anti-reflection (AR) surface treatments are often applied to maintain readability under strong ambient light.

IK10 protection can be combined with different touch technologies:

Impact resistance is primarily achieved through mechanical design; touch technology selection should be based on interaction requirements, not IK rating alone.

IK10 performance depends heavily on how the touchscreen is mounted:

A reinforced screen can still fail if integration design is not considered carefully.

IK10 touchscreens are often paired with:

Impact resistance is most effective when integrated into a fully rugged system design, not treated as a standalone feature.

IK10-rated touchscreens are widely used in environments where durability is non-negotiable:

In these applications, touchscreen failure often leads to system downtime, maintenance costs, and operational disruption.

| الميزة | Standard Industrial Touch | شاشة IK10 تعمل باللمس |

|---|---|---|

| Impact Resistance | معتدل | Maximum (IK10) |

| Vandal Protection | محدودة | عالية |

| Glass Thickness | Standard | Reinforced (6 mm+) |

| Public Use Suitability | محدودة | ممتاز |

| Maintenance Risk | Medium | Low |

For long-term industrial or public-facing deployments, IK10-rated solutions significantly reduce the risk of damage and replacement.

OEM and industrial projects often require:

IK10 touchscreens help meet these requirements by providing mechanical robustness without compromising touch accuracy, supporting reliable long-term operation.

Eagle Touch provides custom IK10 touchscreen solutions for industrial and OEM applications, including:

Our engineering-led approach ensures that impact resistance, usability, and long-term reliability are balanced according to real-world project requirements.

An IK10 touchscreen is strongly recommended if your system:

Selecting the correct IK rating early in the design phase helps prevent costly redesigns and operational issues later.

IK10 touchscreens represent the highest level of impact resistance available for touch-based interfaces.

By combining mechanical strength, industrial-grade design, and reliable touch performance, IK10-rated solutions provide dependable operation in demanding environments.

Choosing an IK10 touchscreen is not just about protection—it is about system continuity, risk reduction, and long-term operational confidence.

🚀 Planning an Impact-Resistant Touch Project?

If you are developing an industrial or public-facing system and need a reliable IK10 touch solution, early specification and proper design selection can significantly reduce risk.

👉 Contact Eagle Touch to discuss your application requirements.

اعتبارات هندسية تتجاوز توافق الإشارات الأساسية في مشاريع الحواسيب الشخصية والشاشات ذات اللوحات الصناعية، اختيار واجهة LCD ...

لماذا لا تعني الحماية العالية من الدخول لا تعني دائمًا موثوقية أعلى في مشاريع الحواسيب الشخصية للوحات الصناعية ...

1. فهم مشاكل شاشات اللمس السعوية تستخدم شاشات اللمس السعوية على نطاق واسع في الأنظمة الصناعية والتجارية بسبب ...

1. فهم الشاشات اللمسية “غير المستجيبة” تشير شاشة اللمس غير المستجيبة إلى حالة يكون فيها الإدخال باللمس ...

شارك طلبك ومتطلباتك الرئيسية لـ الشاشات التي تعمل باللمس أو لوحة أجهزة الكمبيوتر الشخصية. سوف يقوم مهندسونا بمراجعة الجدوى والمخاطر والتوصية باتجاه التكوين الصحيح.