産業用パネルPCとモニターにおけるLCDインターフェースの選択

基本的な信号互換性を超えたエンジニアリングの考慮事項 産業用パネルPCおよびモニタープロジェクトでは、LCDインターフェースの選択が重要です。 ...

Energy efficiency is increasingly important in industrial systems — especially in 24/7 operation, outdoor deployments, and unattended equipment.

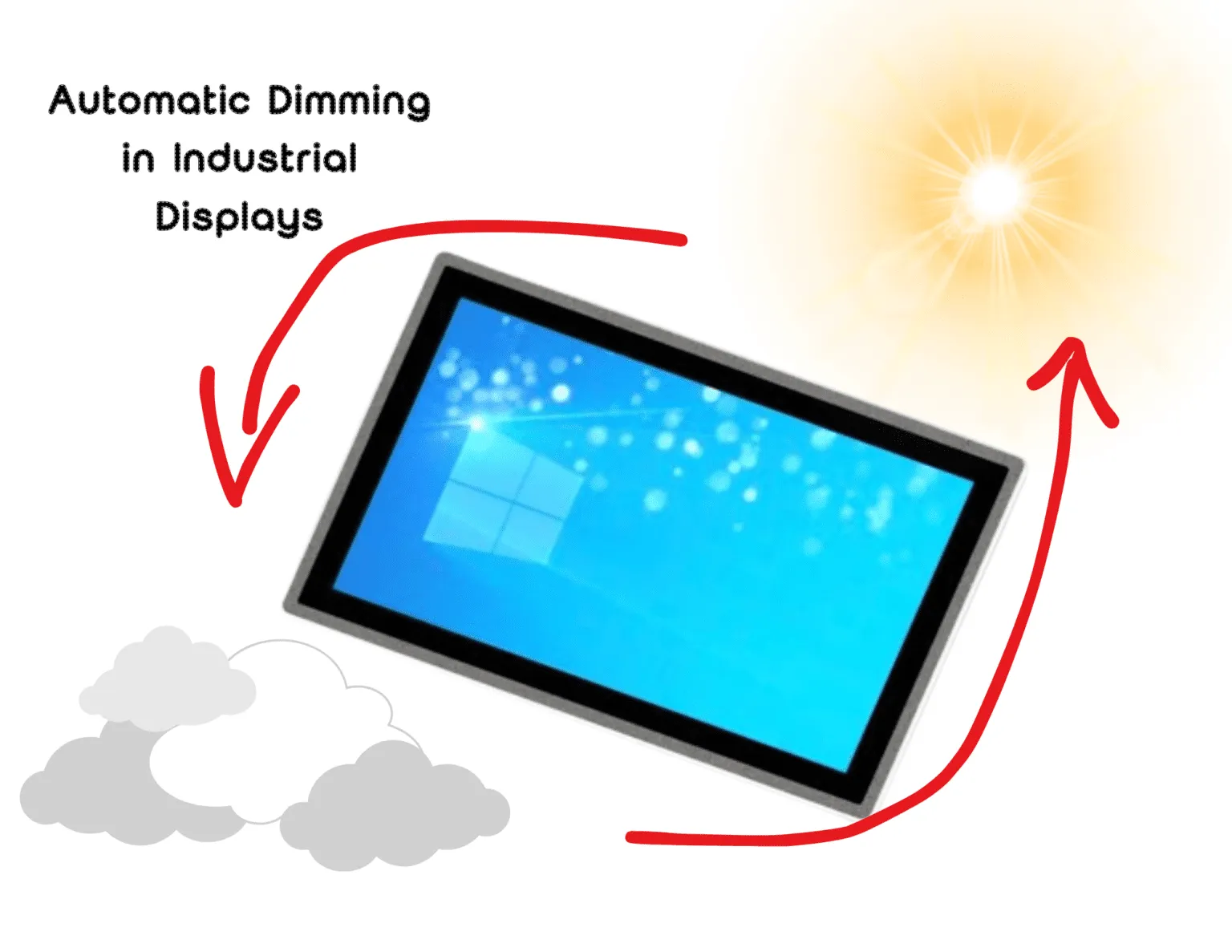

As a result, features such as automatic dimming そして power-saving modes are frequently requested in industrial display specifications.

However, in industrial environments, any automatic behavior must be treated as a system-level decision, not just a feature checkbox.

このリファレンスは次のように説明している。 how automatic dimming and power management work in industrial displays, where they deliver real value, and where they may introduce operational risk.

Industrial displays often operate under conditions very different from consumer electronics:

In these scenarios, unmanaged display brightness can become a major contributor to:

Power control mechanisms exist to address these challenges — but only when properly integrated at system level.

Automatic dimming typically relies on an ambient light sensor that adjusts backlight brightness based on surrounding light conditions.

In industrial implementations, this mechanism usually includes:

When engineered correctly, automatic dimming can:

The key issue is not whether dimming exists, but how it behaves when conditions change or sensors fail.

In industrial systems, automatic brightness adjustment is not always desirable.

In control or safety-related interfaces, unexpected brightness changes may:

For safety-critical HMIs, fixed and validated brightness levels are often preferred.

Automatic dimming depends on sensor input.

If the sensor is:

The display may respond incorrectly.

Industrial designs must define:

In environments with rapidly changing light conditions — such as:

Frequent brightness changes can reduce usability rather than improve it.

Power management in industrial displays goes beyond dimming.

Typical power-saving mechanisms include:

These modes can significantly reduce energy consumption, but they must be coordinated with:

A display that enters power-saving mode too aggressively may appear unresponsive in time-critical operations.

These features are generally well-suited for:

In these cases, energy efficiency and component longevity outweigh constant visual consistency.

Automatic dimming and aggressive power-saving may not be appropriate for:

In such deployments, predictable behavior is often more important than energy optimization.

In industrial display design, power management is not a standalone feature.

It must be evaluated together with:

Many industrial projects enable dimming hardware support but limit or condition its use in software, ensuring predictable system behavior.

This approach balances efficiency with reliability.

If your system includes defined power budgets, outdoor exposure, or unattended operation, brightness and power behavior should be reviewed early in system design.

An engineering review can help determine:

Early decisions prevent late-stage usability and validation issues.

注

This reference focuses on system behavior and integration considerations.

Power-saving features should always be evaluated within the context of the complete industrial system.

基本的な信号互換性を超えたエンジニアリングの考慮事項 産業用パネルPCおよびモニタープロジェクトでは、LCDインターフェースの選択が重要です。 ...

産業用パネルPCプロジェクトにおいて、IP保護等級が高くても信頼性が高いとは限らない理由 ...

1.静電容量式タッチスクリーンの問題を理解する 静電容量式タッチスクリーンは、以下の理由により産業用および商業用システムで広く使用されている。 ...

1.非反応型」タッチスクリーンを理解する 非反応型タッチスクリーンとは、タッチ入力が「非反応型」であることを意味します。 ...

あなたのアプリケーションと主な要件を共有する タッチモニター または パネルPC. 当社のエンジニアは、実現可能性、リスクを検討し、適切な構成の方向性を提案します。.