LCD Interface Selection for Industrial Panel PCs and Monitors

Engineering Considerations Beyond Basic Signal Compatibility In industrial Panel PC and monitor projects, LCD interface selection …

Resistive touchscreens remain one of the most reliable and widely used touch technologies in industrial and professional applications.

Unlike consumer-oriented capacitive touchscreens, resistive touchscreens are pressure-activated and work with fingers, gloves, stylus pens, or any solid object.

Because of their stability, predictability, and environmental resistance, resistive touchscreens continue to be a preferred solution for industrial control systems, medical equipment, and OEM projects requiring long-term availability.

This guide explains:

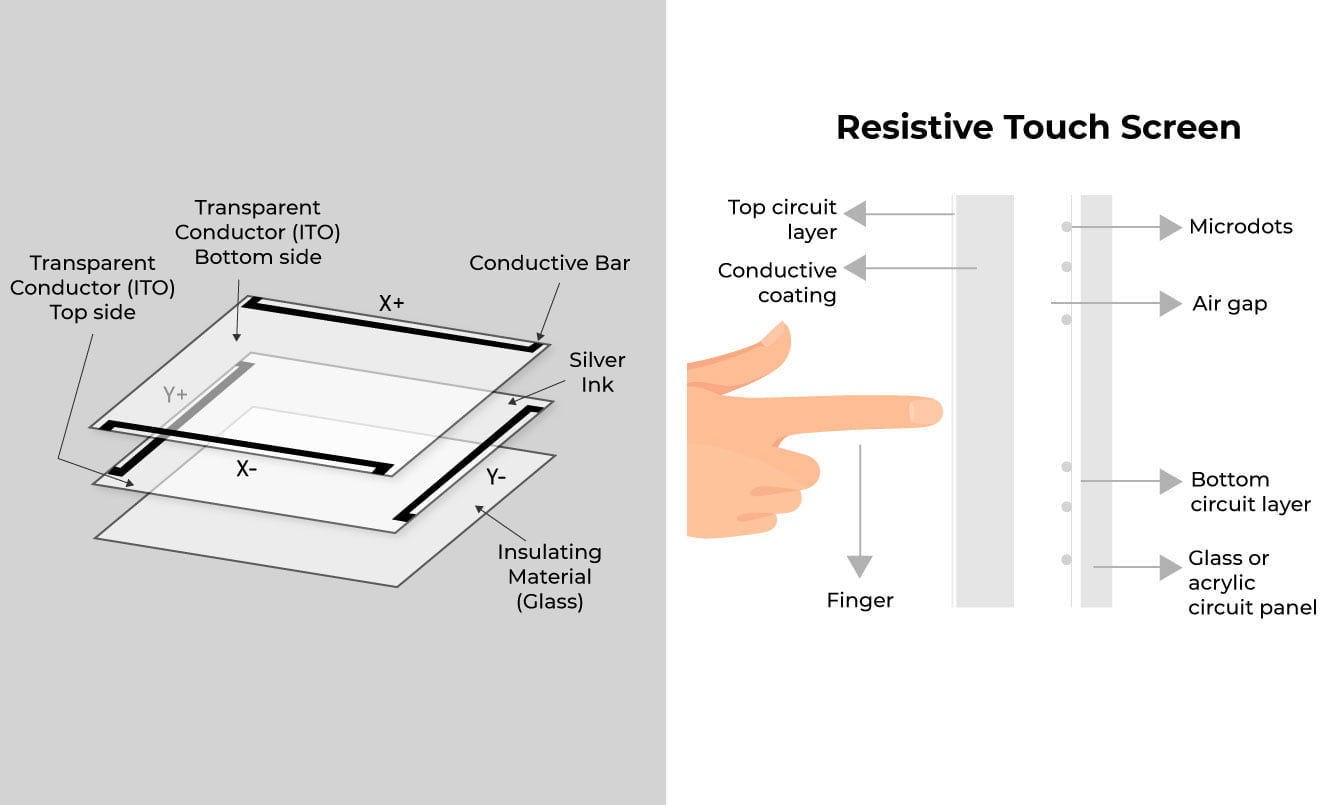

A resistive touchscreen is a pressure-sensitive input device consisting of two transparent conductive layers separated by a thin gap. When pressure is applied, the layers make contact and the controller detects the touch location.

Key characteristics include:

This makes resistive technology especially suitable for industrial, medical, and outdoor applications.

When pressure is applied to the screen:

Because the system relies on physical pressure rather than electrical conductivity, resistive touchscreens function reliably in dusty, wet, or electrically noisy environments.

For applications requiring extended operational life and stable performance, 5-wire resistive technology is generally recommended.

| Feature | Resistive Touchscreen | Capacitive Touchscreen |

|---|---|---|

| Input Method | Pressure-based | Conductivity-based |

| Glove Operation | ✅ Yes | ❌ Limited |

| Stylus Support | ✅ Yes | ❌ Limited |

| Water Resistance | ✅ High | ⚠️ Moderate |

| Multi-touch | ❌ No | ✅ Yes |

| Industrial Stability | ✅ Excellent | ⚠️ Medium |

| Cost Control | ✅ Easier | ❌ Higher |

Resistive touchscreens are application-driven, while capacitive touchscreens are more common in consumer devices.

Resistive touchscreens offer several benefits for industrial and professional use:

These advantages make resistive technology ideal for mission-critical interfaces.

While resistive touchscreens are highly reliable, they do have limitations:

For applications where multi-touch gestures or high visual clarity are essential, capacitive technology may be more suitable.

Resistive touchscreens are commonly used in:

These environments prioritize reliability, predictability, and durability over consumer-style interaction.

OEM and industrial projects often require:

Resistive touchscreens meet these requirements by offering long-term availability and consistent performance, which is critical for industrial programs.

Eagle Touch provides custom resistive touchscreen solutions designed for industrial and OEM applications, including:

Our engineering-led approach ensures that each solution aligns precisely with your application requirements.

A resistive touchscreen is often the best choice if your project requires:

If you are evaluating touch technology for an industrial or OEM application, a resistive touchscreen may provide the most dependable solution.

Engineering Considerations Beyond Basic Signal Compatibility In industrial Panel PC and monitor projects, LCD interface selection …

Why Higher Ingress Protection Does Not Always Mean Higher Reliability In industrial Panel PC projects, IP …

1. Understanding Capacitive Touchscreen Issues Capacitive touchscreens are widely used in industrial and commercial systems due …

1. Understanding “Non-Responsive” Touch Screens A non-responsive touch screen refers to a condition where touch input …

Share your application and key requirements for Touch Monitors or Panel PCs. Our engineers will review feasibility, risks, and recommend the right configuration direction.