LCD Interface Selection for Industrial Panel PCs and Monitors

Engineering Considerations Beyond Basic Signal Compatibility In industrial Panel PC and monitor projects, LCD interface selection …

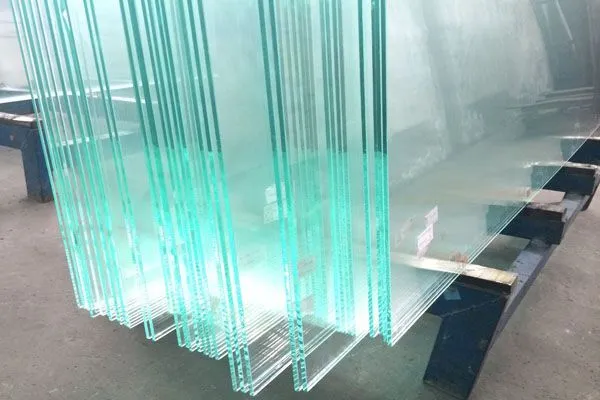

Toughened glass—also known as tempered glass—is a type of safety glass that plays a critical role in industrial equipment, touch displays, kiosks, and public-facing systems.

Compared to ordinary annealed glass, toughened glass offers:

These characteristics make it a standard material choice for industrial touch monitors, ticketing machines, and outdoor display systems.

Toughened glass is a form of safety glass that has been thermally treated to improve its strength and durability.

During manufacturing, the glass is heated to approximately 620–680°C and then rapidly cooled.

This process creates compressive stress on the surface and tensile stress inside the glass.

As a result, toughened glass becomes:

The toughening process involves several key steps:

Once tempered, the glass cannot be cut or drilled without breaking.

Toughened glass can withstand:

This makes it ideal for touch screens used in public or industrial environments.

Toughened glass tolerates temperature differences of up to 200–250°C, far higher than standard glass.

This is essential for applications such as:

When broken, toughened glass shatters into small, blunt fragments rather than sharp shards.

This significantly reduces the risk of injury, which is why it is classified as safety glass.

| Feature | Toughened Glass | Normal Glass |

|---|---|---|

| Strength | Very High | Low |

| Thermal Resistance | High | Low |

| Breakage Safety | Small blunt pieces | Sharp shards |

| Industrial Use | Yes | No |

In touch monitors and industrial displays, toughened glass is commonly used as:

Depending on the project, it can be combined with:

These enhancements improve visibility, durability, and long-term usability.

Toughened glass is widely used in:

Its ability to withstand continuous use, impact, and environmental stress makes it a core material in industrial system design.

Despite its advantages, toughened glass has some limitations:

For this reason, design validation before mass production is critical in industrial projects.

Yes. “Toughened glass” and “tempered glass” refer to the same material.

Yes. With appropriate thickness and coatings, it is widely used in semi-outdoor and outdoor applications.

Typical thickness ranges from 2 mm to 6 mm, depending on screen size and impact requirements.

Toughened glass is not just a safety upgrade—it is a fundamental material choice for modern industrial and touch-based systems.

Its strength, thermal stability, and safe failure behavior make it indispensable for:

For OEMs and system integrators, choosing the right toughened glass specification is a key step toward reliable, long-life product design.

Engineering Considerations Beyond Basic Signal Compatibility In industrial Panel PC and monitor projects, LCD interface selection …

Why Higher Ingress Protection Does Not Always Mean Higher Reliability In industrial Panel PC projects, IP …

1. Understanding Capacitive Touchscreen Issues Capacitive touchscreens are widely used in industrial and commercial systems due …

1. Understanding “Non-Responsive” Touch Screens A non-responsive touch screen refers to a condition where touch input …

Share your application and key requirements for Touch Monitors or Panel PCs. Our engineers will review feasibility, risks, and recommend the right configuration direction.